The Science Behind 250 Amp TIG Torches: Understanding Their Functionality and Applications

The Science Behind 250 Amp TIG Torches: How They Work

Table of Contents

Understanding TIG Welding

What is a 250 Amp TIG Torch?

Key Components of a 250 Amp TIG Torch

The Mechanism of 250 Amp TIG Torches

Applications of 250 Amp TIG Torches

Advantages of Using 250 Amp TIG Torches

Choosing the Right 250 Amp TIG Torch

FAQs about 250 Amp TIG Torches

Understandin

The Science Behind 250 Amp TIG Torches: How They Work

Table of Contents

- Understanding TIG Welding

- What is a 250 Amp TIG Torch?

- Key Components of a 250 Amp TIG Torch

- The Mechanism of 250 Amp TIG Torches

- Applications of 250 Amp TIG Torches

- Advantages of Using 250 Amp TIG Torches

- Choosing the Right 250 Amp TIG Torch

- FAQs about 250 Amp TIG Torches

Understanding TIG Welding

TIG (Tungsten Inert Gas) welding is a precise and versatile welding process utilized in various industries, from automotive to aerospace. This method involves the use of a non-consumable tungsten electrode to produce the weld. The surrounding inert gas, typically argon or helium, protects the weld area from contamination, ensuring a clean and strong bond between the materials being joined. The ability to control the heat input makes TIG welding ideal for welding thin materials and achieving high-quality finishes.

What is a 250 Amp TIG Torch?

A **250 Amp TIG torch** is a specialized tool designed to deliver a maximum output of 250 amps for the welding process. This capacity allows for welding thicker materials while maintaining excellent control over the heat and weld quality. Often used in professional settings, these torches are suitable for various metals, including stainless steel, carbon steel, and non-ferrous metals. The design of a 250 Amp TIG torch incorporates advanced features to enhance performance and comfort during operation.

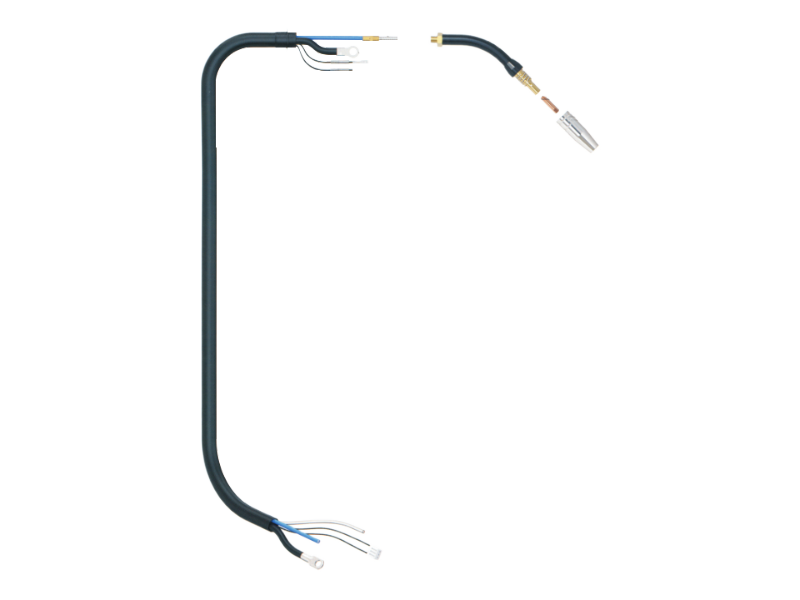

Key Components of a 250 Amp TIG Torch

Understanding the critical components of a 250 Amp TIG torch is essential for grasping how it operates. Below are significant parts that contribute to its functionality:

Tungsten Electrode

The tungsten electrode is the heart of the TIG welding process. It is responsible for creating the arc and transferring heat to the workpiece. The choice of tungsten diameter and composition significantly influences the welding process. For 250 Amp applications, a thicker electrode (e.g., 2.4 mm) is typically used to handle the increased amperage.

Gas Nozzle

The gas nozzle serves to direct the inert gas, providing a protective atmosphere around the weld pool. The size and shape of the nozzle affect the gas flow and coverage, playing a crucial role in preventing oxidation and contamination during welding.

Collet Body and Collet

The collet body holds the tungsten electrode securely in place, while the collet provides a snug fit, ensuring that the electrode remains stable during operation. These components are vital for maintaining precise control over the welding arc.

Cable Connector

The cable connector allows for the attachment of the torch to the power supply, transmitting the electric current necessary for the welding process. A reliable connector is essential for ensuring consistent performance and safety.

Trigger Mechanism

Most 250 Amp TIG torches feature a trigger mechanism that allows the welder to initiate and control the arc with ease. This enhances precision and reduces fatigue, especially during extended welding sessions.

The Mechanism of 250 Amp TIG Torches

The operation of a 250 Amp TIG torch involves several steps that work in harmony to create a successful weld:

1. **Power Supply Connection**: The torch is connected to a suitable power supply capable of delivering the required 250 amps. The welder can adjust the amperage based on the material thickness and welding position.

2. **Electrode Preparation**: The tungsten electrode is prepared by grinding its tip to a point, optimizing it for arc stability and heat generation.

3. **Gas Flow Adjustment**: The inert gas flow is set, ensuring adequate coverage during the welding process while preventing contamination of the weld area.

4. **Arc Initiation**: The welder activates the torch using the trigger mechanism, creating an electric arc between the tungsten electrode and the workpiece. The high temperature generated by the arc melts the base metals and filler rod (if used).

5. **Welding Technique**: The welder moves the torch along the joint, maintaining a consistent distance and angle to ensure proper penetration and fusion of the materials.

6. **Cooling and Inspection**: After completing the weld, the welder allows the joint to cool down, inspecting it for defects or imperfections.

Applications of 250 Amp TIG Torches

250 Amp TIG torches are highly versatile and are used across various industries. Here are some common applications:

Aerospace Engineering

In aerospace, precision is paramount. 250 Amp TIG torches are used to weld lightweight materials, ensuring structural integrity while minimizing weight.

Automotive Manufacturing

Automakers utilize these torches for welding chassis components and exhaust systems, where strong and clean welds are critical.

Metal Fabrication

Fabricators employ TIG welding for creating intricate designs and components, benefiting from the torch's ability to weld thin materials with high accuracy.

Shipbuilding

The marine industry relies on 250 Amp TIG torches for assembling various components of ships, ensuring durability and resistance to harsh environments.

Advantages of Using 250 Amp TIG Torches

The use of 250 Amp TIG torches offers several benefits, making them a preferred choice for many welders:

High Precision and Control

The ability to finely control the heat input allows for high-quality welds even on thin materials, reducing the risk of burn-through.

Versatility

These torches are suitable for various materials and thicknesses, making them ideal for a wide range of welding applications.

Cleaner Welds

The inert gas shielding creates a contamination-free weld area, resulting in cleaner and stronger welds compared to other methods.

Ease of Use

Modern 250 Amp TIG torches are designed for comfort and ergonomics, minimizing fatigue during prolonged use.

Choosing the Right 250 Amp TIG Torch

Selecting the appropriate 250 Amp TIG torch involves several considerations:

Material Type

Consider the materials you will be welding. Some torches are better suited for specific metals, such as aluminum or stainless steel.

Welding Thickness

Evaluate the thickness of the materials to determine if a 250 Amp torch is suitable or if a higher or lower amperage is necessary.

Brand and Model

Research reputable brands and models, looking for user reviews and recommendations from industry professionals.

Accessories and Compatibility

Ensure that the torch is compatible with your existing welding equipment and that you can easily source accessories like tungsten electrodes and gas nozzles.

FAQs about 250 Amp TIG Torches

1. What metals can I weld with a 250 Amp TIG torch?

You can weld a variety of metals, including stainless steel, aluminum, copper, and nickel alloys, with a 250 Amp TIG torch.

2. How do I maintain my TIG torch?

Regularly inspect and clean the torch components, replace worn or damaged parts, and ensure proper gas flow to maintain optimal performance.

3. What size tungsten electrode should I use for a 250 Amp TIG torch?

For 250 Amp applications, a tungsten electrode with a diameter of 2.4 mm is commonly recommended.

4. Can I use a 250 Amp TIG torch for all welding positions?

Yes, with appropriate technique and adjustments, a 250 Amp TIG torch can be used in various welding positions, including flat, horizontal, vertical, and overhead.

5. What is the difference between AC and DC TIG welding?

AC (Alternating Current) is typically used for aluminum and magnesium, while DC (Direct Current) is used for steel and other ferrous metals. A 250 Amp TIG torch can operate on both AC and DC, depending on the power supply.

Conclusion

In summary, the **250 Amp TIG torch** is an indispensable tool in the welding industry, known for its precision, versatility, and ability to produce high-quality welds. By understanding its components, operation, and applications, welders can utilize these torches effectively, ensuring optimal performance and results. As the welding landscape continues to evolve, mastering the science behind these torches will undoubtedly enhance your skills and broaden your capabilities in various welding projects.

TAG:

Previous

Related Posts

The Science Behind 250 Amp TIG Torches: Understanding Their Functionality and Applications

The Science Behind 250 Amp TIG Torches: How They Work

Table of Contents

Understanding TIG Welding

What is a 250 Amp TIG Torch?

Key Components of a 250 Amp TIG Torch

The Mechanism of 250 Amp TIG Torches

Applications of 250 Amp TIG Torches

Advantages of Using 250 Amp TIG Torches

Choosing the Right 250 Amp TIG Torch

FAQs about 250 Amp TIG Torches

Understandin