The Nuts and Bolts of MIG Gun Parts: A Modern Welding Perspective

Understanding MIG Gun Parts: What You Need to Know

Welding is an art, a science, and, let's face it, sometimes a bit of a headache. But if you're in the business of welding, you know that having the right MIG gun parts can make all the difference. Whether you're a seasoned pro or just starting out, understanding the ins and outs of these essential components is crucial for achieving high-quality welds. So, grab your helmet and let's dive into the world of MIG gun parts!

What Are MIG Gun Parts?

First things first, let's break it down. MIG stands for Metal Inert Gas, a welding process that uses a continuous wire feed as an electrode. The MIG gun is the device that feeds this wire to the weld pool, and it comprises several important parts:

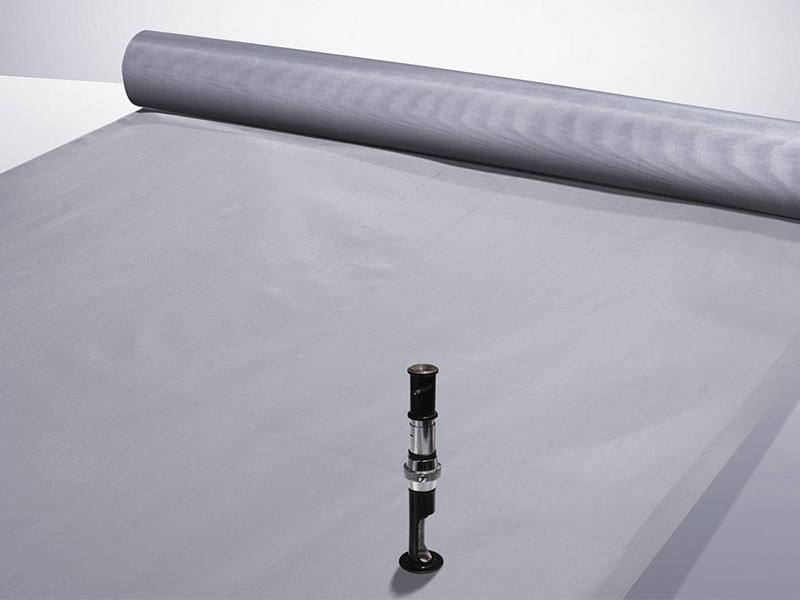

- Nozzle: The part that directs the shielding gas and protects the weld pool.

- Contact Tip: Where the electrical current is delivered to the wire.

- Gas Diffuser: Helps to distribute the shielding gas evenly.

- Trigger: The control mechanism for starting and stopping the welding process.

Why Quality Matters

Now, you might be wondering, "Can't I just go for the cheapest MIG gun parts?" Well, maybe. But here's the kicker: the quality of these parts can significantly affect your welding performance. Poor-quality parts can lead to inconsistent welds, spatter, and even equipment failure. So, investing in quality MIG gun parts can save you time and money in the long run. You know what they say, "Penny wise, pound foolish!"

The Latest Industry Trends

As with any industry, the world of welding is constantly evolving. So, what's hot in the MIG gun parts scene right now? Here are a few trends to keep an eye on:

- Advanced Materials: Manufacturers are utilizing more durable and heat-resistant materials for MIG gun components, resulting in longer-lasting products.

- Ergonomic Designs: New designs focus on operator comfort, making it easier to handle the gun for extended periods.

- Smart Technology: Some MIG guns now feature digital displays and sensors that provide real-time feedback, helping welders make instant adjustments.

Choosing the Right MIG Gun Parts

So, how do you choose the right MIG gun parts for your needs? Here are a few tips:

- Compatibility: Always check that the parts are compatible with your welding machine.

- Quality Certification: Look for parts that meet industry standards and certifications.

- Reviews and Recommendations: Don't hesitate to ask fellow welders for their opinions or check online reviews.

Maintenance Tips for Longevity

Once you've got your MIG gun parts sorted, it's essential to keep them in tip-top shape. Here are some handy maintenance tips:

- Regular Cleaning: Build-up of spatter can affect performance, so clean your nozzle and contact tip frequently.

- Inspect for Wear: Regularly check for signs of wear and tear, and replace parts as necessary.

- Proper Storage: Store your MIG gun in a cool, dry place to prevent damage from moisture.

Final Thoughts

In the fast-paced world of welding, staying ahead of the curve with quality MIG gun parts can make a world of difference. It's all about efficiency, quality, and ultimately, getting the job done right. So, keep your gear in check, stay updated with industry trends, and you'll be well on your way to becoming a welding wizard!

TAG:

Previous

Previous:

Related Posts

The Nuts and Bolts of MIG Gun Parts: A Modern Welding Perspective