Unlocking the Secrets of MIG Gun Parts: A Welder's Guide

Understanding MIG Gun Parts

Alright, let’s dive right in! If you’re in the welding game, you’ve probably heard the term MIG Gun parts popping up quite a bit. But what exactly are these parts, and why should you care? Well, buckle up, because we’re about to explore the nuts and bolts of MIG welding—literally!

What is a MIG Gun?

MIG stands for Metal Inert Gas, which is a bit of a mouthful, right? But essentially, it’s a process that uses a continuous feed of wire to create strong welds. The MIG gun is the magic wand that you wield to make that happen. It’s the tool that allows you to control the flow of the welding wire and the shielding gas. Without it, you might as well be trying to cook a gourmet meal without a stove!

Key Components of MIG Gun Parts

Now, let’s take a closer look at some crucial MIG Gun parts that every welder should know:

1. Contact Tip

The contact tip is where it all begins. This part conducts the electric current to the welding wire. It’s like the heart of the operation. If it wears out, it can cause a lot of headaches—think poor arc stability and inconsistent welds. So, keep an eye on it!

2. Nozzle

The nozzle protects the contact tip and helps direct the shielding gas. It’s also the part that gets the most splatter. If you notice it’s getting clogged, it’s time for a good clean or, sometimes, a replacement. Just like a dirty windshield can obscure your view, a clogged nozzle can hinder your welding performance.

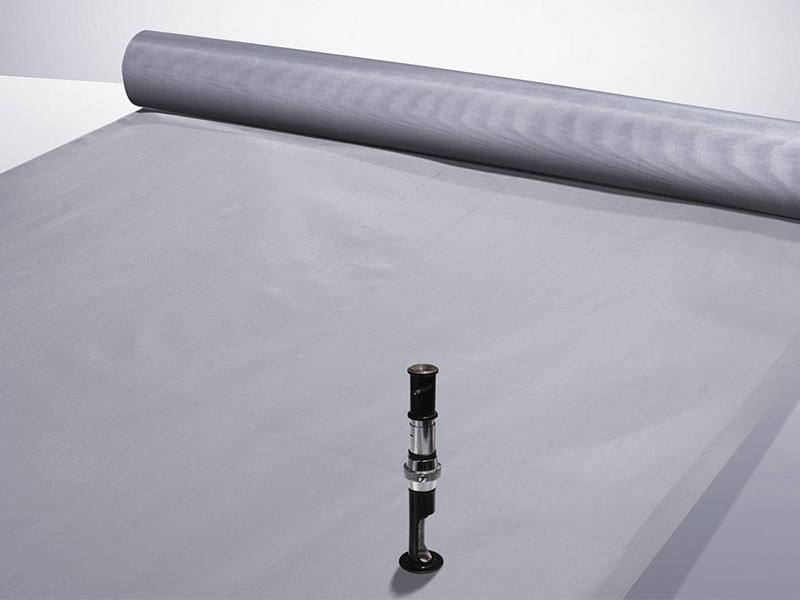

3. Liners

These are the tubes that guide the welding wire through the MIG gun. Over time, they can become worn or kinked, which leads to feeding issues. If your wire isn't feeding smoothly, check the liner first. After all, no one wants a wire jam while they’re in the zone!

4. Gas Diffuser

The gas diffuser is essential for evenly distributing the shielding gas around the weld area. If it malfunctions, the gas flow can become erratic, leading to poor weld quality. It’s like throwing a party without enough snacks—nobody’s gonna be happy!

Maintaining Your MIG Gun Parts

Now that you know what makes up a MIG gun, let’s talk maintenance. Just like a car needs regular oil changes, your MIG gun needs some TLC too. Here are a few tips to keep it in tip-top shape:

- Regular Cleaning: Make it a habit to clean the nozzle and contact tip after each use. A clean gun means better performance!

- Inspect for Wear: Before you start a new project, check all parts for signs of wear. Don’t let a small problem turn into a big headache.

- Keep It Cool: Overheating can damage many components, so avoid prolonged use without breaks. It’s not a marathon; it’s a relay race!

When to Replace MIG Gun Parts

Even with the best care, there comes a time when you have to face the music and replace some parts. If you notice irregularities in your welds, or if the wire feed is inconsistent, it might be time for new MIG Gun parts. Don’t wait until it’s too late—sometimes, a small investment today can save you a lot of trouble tomorrow!

Final Thoughts

In conclusion, understanding and maintaining your MIG gun parts is crucial for any welder looking to produce quality work. Remember, your MIG gun is only as good as the parts that make it up. So, treat it right, and it will reward you with smooth, strong welds for years to come. Happy welding!

TAG:

Previous:

Related Posts

Unlocking the Secrets of MIG Gun Parts: A Welder's Guide