Unlocking the Magic of MIG Gun Parts: A Comprehensive Guide

What are MIG Gun Parts?

MIG welding, short for Metal Inert Gas welding, is one of the most popular methods for joining metals. But what makes it so effective? The answer lies in its essential components: the MIG gun parts. These parts work together like a finely-tuned orchestra, creating the perfect harmony needed for a successful weld. Let’s dive into the nitty-gritty of these components, shall we?

The Key Players in Your MIG Gun

When you think of a MIG gun, it’s easy to imagine a sleek tool in your hands, but what’s under the hood? Here are the main players:

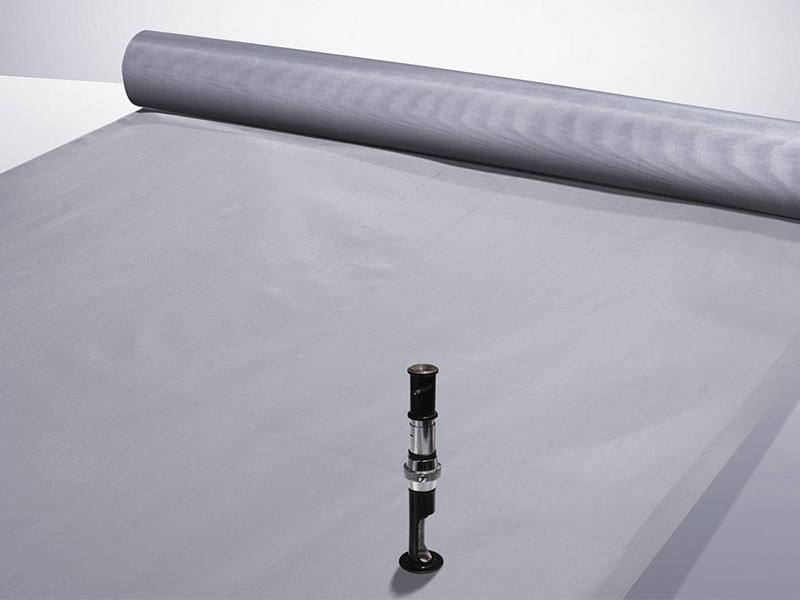

- Nozzle: This is the front line of your gun, directing the shielding gas and helping to shape the weld pool.

- Contact Tip: It’s the unsung hero that conducts the welding current, ensuring your weld is as solid as a rock.

- Diffuser: This part blends the gas flow, creating a protective cloud around your weld. Think of it as an invisible shield!

- Trigger: It may seem simple, but this part controls the entire operation. Pull it, and it’s game on!

Types of MIG Gun Parts

Not all MIG gun parts are created equal, my friend! Depending on your welding project, you might need different types. Here’s a rundown:

- Air-Cooled vs. Water-Cooled: Air-cooled guns are lighter and easier to handle, while water-cooled options are perfect for heavy-duty jobs, keeping everything cool.

- Standard vs. Heavy-Duty Nozzles: If you’re welding thicker materials, heavy-duty nozzles are your best bet. They can handle more heat and wear.

- Interchangeable Tips: Some models allow you to swap tips for various wire sizes, making your gun versatile.

Maintaining Your MIG Gun Parts

Alright, let’s get real. If you want your MIG gun to last, maintenance is key. Here are some tips:

- Regular Cleaning: After each use, clean the nozzle and tip to prevent buildup. A little elbow grease goes a long way!

- Inspect for Damage: Check for wear and tear. If a contact tip looks worn out, don’t hesitate to replace it. It’s like changing the oil in your car—necessary!

- Proper Storage: Keep your MIG gun in a dry place, away from moisture. Believe me, rust is a killer.

Common Problems and Solutions

Even the best tools can hit a snag. Here are a few common issues with MIG gun parts and how to tackle them:

- Wire Feeding Issues: If the wire isn’t feeding smoothly, check for kinks or tangles in the spool. Make sure the tension is just right!

- Porosity in Welds: This can happen if the shielding gas isn’t flowing properly. Ensure your gas lines are tight and leak-free.

- Overheating: If your gun is overheating, you might need a heavier-duty gun or to take more breaks. Your tool needs love, too!

Wrapping Up

So there you have it! With the right knowledge about MIG gun parts, you’re ready to tackle any welding challenge that comes your way. Remember, every great welder started where you are now—so don’t sweat it! Get out there, practice, and let those sparks fly!

TAG:

Previous:

Related Posts

Unlocking the Magic of MIG Gun Parts: A Comprehensive Guide