Essential Guide to TIG Torch Hose: Key Considerations for Optimal Welding Performance

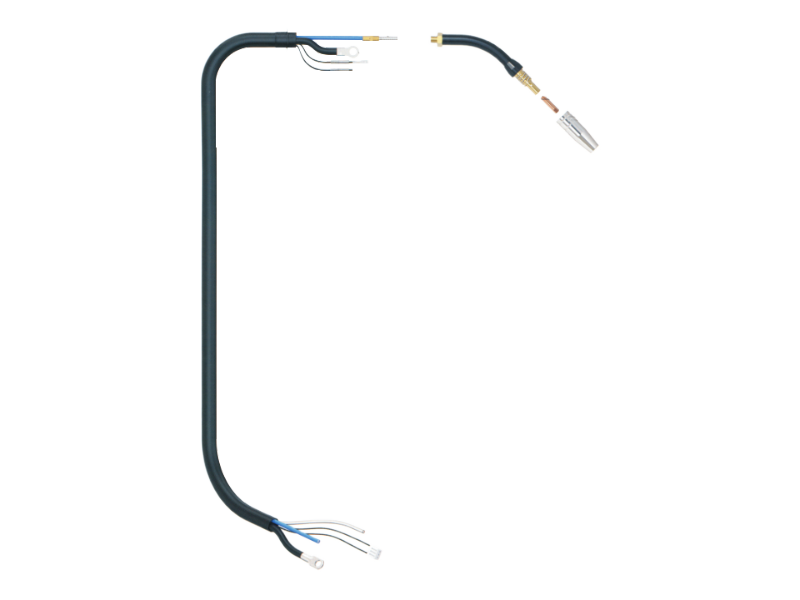

TIG (Tungsten Inert Gas) welding is a popular method among professionals for its precision and versatility. One of the critical components of a TIG welding setup is the TIG torch hose. This hose serves as the lifeline, delivering the necessary shielding gas and connecting the torch to the gas supply. Choosing the right TIG torch hose can significantly affect your welding performance, efficiency, a

TIG (Tungsten Inert Gas) welding is a popular method among professionals for its precision and versatility. One of the critical components of a TIG welding setup is the TIG torch hose. This hose serves as the lifeline, delivering the necessary shielding gas and connecting the torch to the gas supply. Choosing the right TIG torch hose can significantly affect your welding performance, efficiency, and safety.

When selecting a TIG torch hose, several factors must be considered. First, the hose's material is paramount. Most hoses are made from rubber or PVC, each offering unique benefits. Rubber hoses are typically more flexible and resistant to abrasion, making them suitable for demanding work environments. PVC hoses, on the other hand, may offer better resistance to certain chemicals, but they could be less flexible in colder temperatures.

Another essential aspect is the hose's diameter. A properly sized hose ensures optimal gas flow and pressure, which are critical for achieving a stable arc and preventing contamination during the welding process. Typically, a diameter of 3/16 inches is standard for most TIG welding applications, but always refer to your welder's specifications for guidance.

Additionally, pay attention to the length of the TIG torch hose. While longer hoses can provide better mobility and reach, they may also lead to gas pressure drops, which can negatively impact the welding process. Striking a balance between length and performance is key, and it's advisable to keep the hose as short as necessary for your specific tasks.

Over time, hoses can wear out due to exposure to heat, abrasion, or chemicals. Regular inspections for cracks, leaks, or kinks are essential to ensure continued performance and safety. If any damage is detected, it is important to replace the hose promptly to prevent any welding issues or hazards.

Lastly, compatibility is a crucial element when choosing a TIG torch hose. Ensure that the hose fits securely with your TIG torch and gas supply connections to prevent leaks and ensure efficient gas flow. It’s beneficial to check the manufacturer’s specifications for the recommended hose types and sizes.

In summary, a well-chosen TIG torch hose is essential for enhancing your welding performance and ensuring safety. By carefully considering the material, diameter, length, and compatibility of the hose, you can optimize your welding setup for the best results. Understanding these elements will help you make informed decisions that contribute to effective and efficient welding operations.

When selecting a TIG torch hose, several factors must be considered. First, the hose's material is paramount. Most hoses are made from rubber or PVC, each offering unique benefits. Rubber hoses are typically more flexible and resistant to abrasion, making them suitable for demanding work environments. PVC hoses, on the other hand, may offer better resistance to certain chemicals, but they could be less flexible in colder temperatures.

Another essential aspect is the hose's diameter. A properly sized hose ensures optimal gas flow and pressure, which are critical for achieving a stable arc and preventing contamination during the welding process. Typically, a diameter of 3/16 inches is standard for most TIG welding applications, but always refer to your welder's specifications for guidance.

Additionally, pay attention to the length of the TIG torch hose. While longer hoses can provide better mobility and reach, they may also lead to gas pressure drops, which can negatively impact the welding process. Striking a balance between length and performance is key, and it's advisable to keep the hose as short as necessary for your specific tasks.

Over time, hoses can wear out due to exposure to heat, abrasion, or chemicals. Regular inspections for cracks, leaks, or kinks are essential to ensure continued performance and safety. If any damage is detected, it is important to replace the hose promptly to prevent any welding issues or hazards.

Lastly, compatibility is a crucial element when choosing a TIG torch hose. Ensure that the hose fits securely with your TIG torch and gas supply connections to prevent leaks and ensure efficient gas flow. It’s beneficial to check the manufacturer’s specifications for the recommended hose types and sizes.

In summary, a well-chosen TIG torch hose is essential for enhancing your welding performance and ensuring safety. By carefully considering the material, diameter, length, and compatibility of the hose, you can optimize your welding setup for the best results. Understanding these elements will help you make informed decisions that contribute to effective and efficient welding operations.

TAG:

Previous:

Related Posts

Essential Guide to TIG Torch Hose: Key Considerations for Optimal Welding Performance

TIG (Tungsten Inert Gas) welding is a popular method among professionals for its precision and versatility. One of the critical components of a TIG welding setup is the TIG torch hose. This hose serves as the lifeline, delivering the necessary shielding gas and connecting the torch to the gas supply. Choosing the right TIG torch hose can significantly affect your welding performance, efficiency, a