Unpacking the Essential MIG Gun Parts: A Deep Dive into the Industry

Understanding MIG Gun Parts

When it comes to welding, a MIG gun is the unsung hero of the operation. But what exactly are MIG gun parts, you ask? Well, they're the backbone of the MIG welding process, ensuring that everything runs smoothly and efficiently. Without these nifty components, you'd be left with a hodgepodge of metal and a real headache!

The Anatomy of a MIG Gun

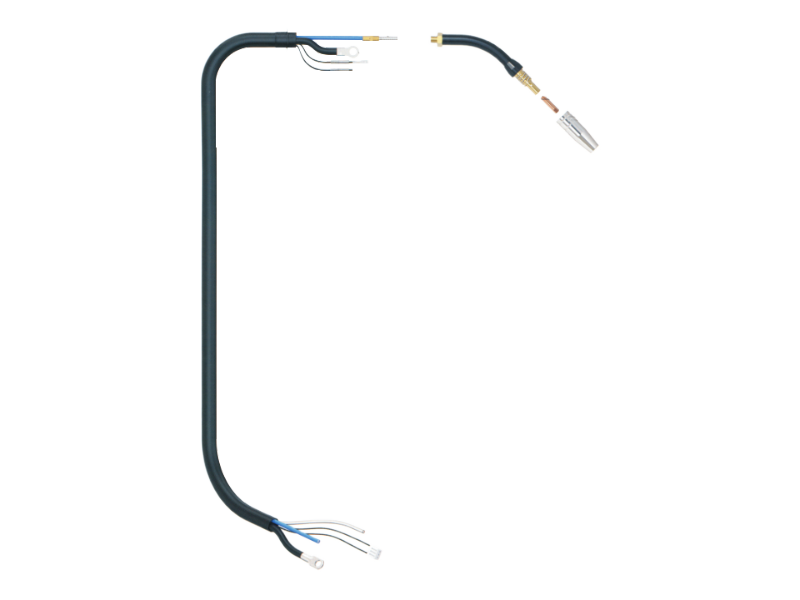

Let's break it down, shall we? A MIG gun is made up of several key parts, each playing a crucial role:

- Contact Tip: This little guy is where the magic happens. It's the part that feeds the welding wire and creates the arc.

- Nozzle: Think of this as the protective shield. It directs the shielding gas to protect the weld pool from contamination.

- Power Cable: This cable connects the gun to the power source. No power, no welding; it's that simple!

- Gas Hose: As the name suggests, this hose carries the shielding gas from the tank to the nozzle.

Making Sense of Each Part

Each component of the MIG gun plays a distinct role, but they all work together like a well-oiled machine. A malfunction in one part can throw a wrench in the whole operation. So, understanding how each part functions is essential for any welding enthusiast or professional.

Common Issues with MIG Gun Parts

Now, let's chat about the issues that can arise. Whether you're a seasoned pro or just starting out, you've likely encountered some snags along the way. Some common problems include:

- Burned Contact Tips: These tips can wear out quickly if the settings aren't right, leading to poor arc stability.

- Nozzle Clogging: Spatter can build up, causing a blockage that hampers gas flow. Time for a cleaning!

- Gas Leaks: A leaky hose can cause all sorts of trouble. Keep an eye on your connections!

Preventative Maintenance Tips

To avoid these pitfalls, it's crucial to practice good maintenance. Here are a few tips that can save you time and money:

- Regularly check and replace contact tips as needed.

- Keep nozzles clean and free of debris.

- Inspect gas hoses for wear and tear.

By following these simple steps, you'll extend the life of your MIG gun parts and ensure a smoother welding experience.

Real-World Applications of MIG Gun Parts

Now, let's shift gears and look at how these parts play out in real-world applications. From automotive repairs to construction projects, MIG welding is everywhere!

Case Study: Automotive Industry

Take the automotive industry, for instance. MIG welding is often used for fabricating parts and repairing frames. The reliability of MIG gun parts is paramount, as even a slight imperfection can lead to safety issues down the line. Mechanics need to trust their equipment, and understanding the intricacies of MIG gun parts is part of that trust.

The Future of MIG Welding

So, what does the future hold for MIG gun parts? With advancements in technology, we can expect more durable materials and innovative designs that improve efficiency and reduce wear. As industries continue to evolve, so too will the components that make them tick.

In Conclusion

In wrapping this up, it's clear that understanding MIG gun parts is crucial for anyone involved in welding. By knowing how each piece functions and how to maintain it, you'll not only improve your skills but also ensure the longevity of your equipment. So, gear up and get ready to tackle your next welding project with confidence!

TAG:

Related Posts

The Science Behind 250 Amp TIG Torches: Understanding Their Functionality and Applications