Essential Safety Tips for Using MIG Welding Torches: A Comprehensive Guide

Essential Safety Tips for Using MIG Welding Torches

Introduction to MIG Welding Safety

MIG welding, or Metal Inert Gas welding, is a highly efficient process that uses electric arcs to melt and join metals. While it's an invaluable skill in various industries, the potential dangers associated with using MIG welding torches cannot be overlooked. Proper safety precautions are essential to ensure a s

Essential Safety Tips for Using MIG Welding Torches

Introduction to MIG Welding Safety

MIG welding, or Metal Inert Gas welding, is a highly efficient process that uses electric arcs to melt and join metals. While it's an invaluable skill in various industries, the potential dangers associated with using MIG welding torches cannot be overlooked. Proper safety precautions are essential to ensure a safe working environment and to protect the welder and others nearby. In this guide, we will delve deep into vital safety tips for using MIG welding torches effectively.

Understanding the Importance of Safety in MIG Welding

MIG welding involves high temperatures and the use of hazardous materials, making it crucial to adhere to safety protocols. The dangers include:

- **Exposure to Flames and Heat**: Welding generates intense heat, posing a risk of burns or fires.

- **Fume Inhalation**: Welding produces fumes that can be harmful if inhaled without proper ventilation.

- **Electric Shock**: Improper handling of equipment can lead to severe electrical hazards.

- **Eye Injuries**: The bright arc can cause serious eye damage if protective gear is not worn.

Understanding these risks is vital for implementing the necessary safety measures.

Personal Protective Equipment (PPE) for MIG Welding

Choosing the Right Gear

The right personal protective equipment is your first line of defense when working with MIG welding torches. Essential PPE includes:

- **Welding Helmet**: Protects your eyes and face from the intense light and heat generated by the welding arc. Ensure it has an appropriate shade number (typically 10-14) to filter harmful rays.

- **Welding Gloves**: Made from heat-resistant materials, these gloves protect your hands from heat, sparks, and sharp metal edges.

- **Flame-Resistant Clothing**: Wear long-sleeved shirts and pants made from flame-resistant materials to prevent burns.

- **Steel-Toed Boots**: Protect your feet from falling objects and sparks.

- **Respirators**: Depending on the ventilation of your workspace, a respirator may be necessary to filter out harmful fumes.

Maintaining Your PPE

Regularly inspect your PPE for any signs of wear and tear. Replace any damaged equipment immediately to ensure your safety while welding.

Setting Up a Safe Welding Environment

Choosing the Right Location

Select a well-ventilated area free from flammable materials. If welding indoors, use exhaust fans or fume extraction systems to minimize fume inhalation. Ensure that there’s enough space to maneuver without bumping into objects or other people.

Fire Safety Measures

Keep a fire extinguisher nearby, and familiarize yourself with its operation. It's recommended to have a Class D fire extinguisher, specifically designed for metal fires. Additionally, remove or protect any materials that could catch fire, such as cardboard, paper, or plastics.

Proper Handling of MIG Welding Equipment

Understanding Your Equipment

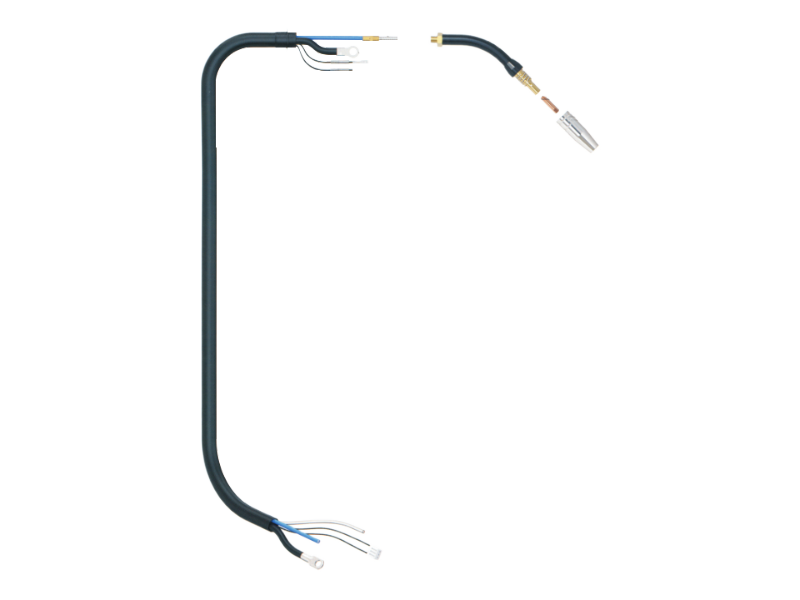

Familiarize yourself with your MIG welding torch and its components. Key components include:

- **Contact Tip**: Responsible for transferring the electric current to the welding wire.

- **Gas Diffuser**: Helps regulate the flow of shielding gas.

- **Nozzle**: Directs the flow of gas and protects the contact tip.

Understanding how each part operates helps prevent accidents during use.

Correctly Setting Up Your MIG Welder

Ensure all connections are secure before starting. Double-check that the gas cylinders are correctly set up and that there are no leaks. Regularly inspect hoses for cracks or wear. Use a gas detector if available to monitor for leaks.

Proper Welding Technique

When using your MIG welding torch, maintain a firm grip and keep the torch at the correct angle (typically 15-20 degrees). Move the torch steadily to create consistent welds, and avoid excessive heat that could lead to burn-through or warping.

Electrical Safety in MIG Welding

Avoiding Electric Shock

To minimize the risk of electric shock, follow these guidelines:

- **Use Grounded Equipment**: Ensure your welder is properly grounded to prevent electrical hazards.

- **Keep Dry**: Always work in dry conditions, avoiding wet surfaces that can conduct electricity.

- **Inspect Cables**: Regularly check cables and connections for damage. Replace any frayed or exposed wires.

Understanding Electrical Ratings

Familiarize yourself with your MIG welder's electrical ratings, including input voltage and amperage. Ensure your power source can handle the load to prevent electrical failures or fires.

Ventilation and Fume Control

Importance of Good Air Quality

Welding produces harmful fumes, which can lead to respiratory illness if inhaled over time. Always ensure adequate ventilation in your workspace. When working in confined areas, consider using air-purifying respirators or local exhaust ventilation systems.

Fume Extraction Systems

If your workplace generates a significant amount of welding fumes, investing in a dedicated fume extraction system is essential. These systems capture harmful particles before they enter the welder's breathing zone, significantly improving air quality.

Post-Welding Safety Checks

Properly Cooling Equipment

After completing your welding work, allow the torch and other equipment to cool down before handling. This will prevent burns and injuries. Always store equipment properly in a designated area to avoid damage and accidental activation.

Inspecting the Work Area

Check your workspace for any potential hazards after welding. Ensure that all tools and materials are stored safely, and clean up any debris to prevent accidents.

Additional Safety Tips for Beginners

Take a Welding Class

If you're new to MIG welding, consider taking a class to learn best practices and safety protocols from experienced instructors. Hands-on training can significantly reduce the likelihood of accidents.

Learn from Experienced Welders

Mentorship can be invaluable. Work alongside seasoned welders who can provide practical tips and advice on safe welding practices.

Frequently Asked Questions (FAQs)

1. What should I wear while MIG welding?

When MIG welding, it's crucial to wear flame-resistant clothing, a welding helmet with appropriate shading, gloves, and steel-toed boots. Ensure all clothing is free of holes and loose fittings.

2. How can I protect my eyes while welding?

Using a welding helmet is the best way to protect your eyes from the intense light and UV radiation created during the welding process. Ensure it has a proper shade rating for the type of welding you're doing.

3. Is it necessary to have ventilation when welding indoors?

Yes, adequate ventilation is essential to prevent the accumulation of harmful fumes. Use exhaust fans, open windows, or welding fume extraction systems to maintain good air quality.

4. What should I do in case of an electrical shock?

If someone receives an electrical shock, do not touch them until the power source is turned off. Call for emergency assistance immediately and provide first aid if trained to do so.

5. How often should I inspect my welding equipment?

Regular inspections should be conducted before each use. Check cables, connections, and the condition of your MIG torch and other equipment for any signs of wear or damage.

Conclusion

Utilizing MIG welding torches can be a rewarding skill, but it comes with its own set of hazards that must be managed through diligent safety practices. By equipping yourself with the right personal protective equipment, understanding your workspace, and following established safety protocols, you can minimize risks and ensure a safe welding environment. Remember, safety is not just about following rules; it's about cultivating a mindset that prioritizes well-being in every welding project you undertake.

TAG:

Related Posts

Essential Safety Tips for Using MIG Welding Torches: A Comprehensive Guide

Essential Safety Tips for Using MIG Welding Torches

Introduction to MIG Welding Safety

MIG welding, or Metal Inert Gas welding, is a highly efficient process that uses electric arcs to melt and join metals. While it's an invaluable skill in various industries, the potential dangers associated with using MIG welding torches cannot be overlooked. Proper safety precautions are essential to ensure a s