Unlocking the Potential of Your 250 Amp TIG Torch: Techniques to Try for Superior Welding Results

Unlocking the Potential of Your 250 Amp TIG Torch: Techniques to Try for Superior Welding Results

Welding is a craft that demands precision, skill, and the right tools. Among these, the TIG (Tungsten Inert Gas) torch stands out for its versatility and capability, especially the 250 Amp models, which are ideal for a variety of applications. In this article, we will delve into techniques that can help you harness the full potential of your 250 Amp TIG torch, whether you're a professional welder or a DIY enthusiast.

Table of Contents

- Understanding Your 250 Amp TIG Torch

- Essential Components of a 250 Amp TIG Torch

- Selecting the Right Tungsten Electrode

- Choosing the Correct Filler Material

- Setting Up for Success: Preparing Your Workspace

- Techniques to Enhance Welding Performance

- Controlling Heat Input

- Mastering TIG Welding Techniques

- Common Mistakes and How to Avoid Them

- Advanced Techniques for Professional Welds

- Maintaining Your 250 Amp TIG Torch

- FAQs About TIG Welding

- Conclusion

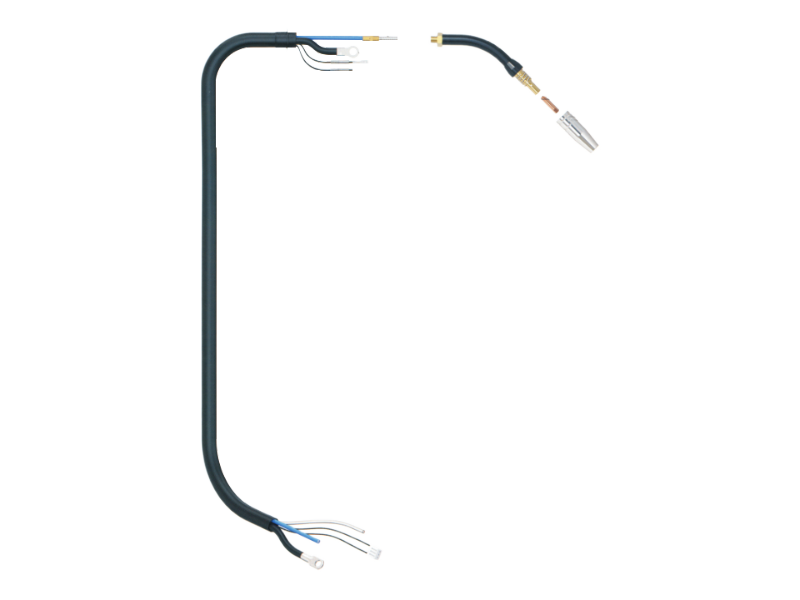

Understanding Your 250 Amp TIG Torch

The 250 Amp TIG torch is a powerful tool capable of providing high-quality welds on various materials, including steel, stainless steel, and aluminum. Its design allows for precise control over the welding process, making it a favored choice among professionals. Understanding the functionality of your TIG torch is essential for achieving optimal results.

What is TIG Welding?

TIG welding is a process that uses a non-consumable tungsten electrode to produce the weld. The shielding gas, usually argon, protects the weld area from contamination. This method is known for creating clean, strong welds, making it ideal for intricate work and thin materials.

Essential Components of a 250 Amp TIG Torch

Familiarity with the essential components of your TIG torch will enable you to optimize its use effectively. Here are the critical parts:

Tungsten Electrode

The tungsten electrode is paramount in TIG welding. It must be correctly sized and shaped for your specific application. A sharp point is typically used for precise welding, while a balled tip is ideal for thicker materials.

Gas Lens

A gas lens is an optional feature that enhances gas flow and provides better shielding. It helps in reducing turbulence, which can lead to contamination of the weld pool.

Collet and Collet Body

The collet holds the tungsten electrode in place. It's vital to ensure that the collet is the right size for your electrode to maintain a solid grip and prevent movement during welding.

Selecting the Right Tungsten Electrode

Selecting the appropriate tungsten electrode is crucial for achieving high-quality welds. The choice depends on several factors, including the material being welded and the thickness of the workpieces.

Types of Tungsten Electrodes

There are three primary types of tungsten electrodes: pure tungsten, thoriated tungsten, and lanthanated tungsten. Each type has its advantages, and understanding when to use each will enhance your welding performance.

Pure Tungsten

Pure tungsten is best for AC welding applications like aluminum. It provides good arc stability and is less prone to contamination.

Thoriated Tungsten

Thoriated tungsten is highly favored for DC welding. It provides excellent heat resistance and is better for welding steel and stainless steel.

Lanthanated Tungsten

Lanthanated tungsten electrodes combine benefits from both pure and thoriated electrodes, offering good arc stability and a longer lifespan.

Choosing the Correct Filler Material

Choosing the right filler material is equally important. The filler should complement the base metal being welded, ensuring a strong bond and reducing the risk of defects.

Types of Filler Rods

Filler rods come in various materials and diameters. Common materials include ER70S-6 for steel, 4047 for aluminum, and ER308L for stainless steel. Selecting the appropriate material will enhance the quality of the weld.

Setting Up for Success: Preparing Your Workspace

A well-organized workspace can significantly affect the outcome of your welding project. Consider the following tips before starting:

Safety First

Welding involves risks, including exposure to harmful fumes and intense light. Always wear appropriate safety gear, including gloves, a welding helmet, and protective clothing.

Workspace Organization

Ensure your workspace is clean and free of clutter. Having all necessary tools and materials within reach will streamline your workflow.

Techniques to Enhance Welding Performance

Now that your workspace is ready, let's explore techniques that can elevate your welding skills:

Controlling Heat Input

Controlling the heat input is critical in TIG welding. Too much heat can lead to warping and burn-through, while too little can result in poor fusion. Adjusting your amperage settings according to the material thickness and type is essential.

Mastering TIG Welding Techniques

Practicing various welding techniques can help you become more proficient. Here are some techniques to try:

Weaving Technique

The weaving technique involves moving the torch in a side-to-side motion to create a wider bead. This is particularly useful for thicker materials.

Stringer Bead Technique

The stringer bead technique involves a steady, linear motion to create narrower beads. This method is ideal for thin materials and intricate welds.

Common Mistakes and How to Avoid Them

Even experienced welders can make mistakes. Here are some common pitfalls and how to avoid them:

Insufficient Cleaning

Failing to clean the base metal can lead to contamination and weak welds. Always ensure surfaces are free of rust, oils, and other contaminants.

Poor Torch Angle

The angle of the torch significantly impacts the quality of the weld. Maintain a consistent angle of 15-20 degrees for optimal results.

Advanced Techniques for Professional Welds

For those looking to take their welding to the next level, consider the following advanced techniques:

Pulsed TIG Welding

Pulsed TIG welding allows for better control over heat input and can reduce distortion in thin materials. This technique involves oscillating the amperage, creating a pulsing effect.

TIG Welding Aluminum

Welding aluminum requires specific techniques due to its thermal properties. Using a larger diameter tungsten electrode and a higher gas flow rate can help achieve better results.

Maintaining Your 250 Amp TIG Torch

Proper maintenance of your TIG torch ensures longevity and consistent performance. Follow these tips for keeping your torch in top shape:

Regular Cleaning

After each use, clean the torch components, including the collet and gas lens, to prevent buildup that can affect performance. Use a soft brush or cloth to remove residue.

Inspecting Components

Regularly inspect the tungsten electrode, collet, and gas lens for wear and tear. Replacing worn components promptly can prevent welding issues.

FAQs About TIG Welding

What materials can I weld with a 250 Amp TIG torch?

You can weld various materials, including steel, stainless steel, aluminum, copper, and even some alloys, with a 250 Amp TIG torch.

How do I choose the right tungsten electrode for my project?

Consider the material type and thickness. For instance, use pure tungsten for aluminum and thoriated tungsten for steel welding.

What should I do if my welds are coming out uneven?

Uneven welds can result from inconsistent heat input, incorrect torch angle, or contamination. Review your technique and workspace setup to identify potential issues.

Can I use a 250 Amp TIG torch for thin materials?

Yes, but you need to control the heat input carefully to avoid burn-through. Techniques like stringer beads may be beneficial.

How often should I maintain my TIG torch?

Regular maintenance is optimal after each use. Check components for wear and clean them to ensure consistent performance.

Conclusion

Unlocking the full potential of your 250 Amp TIG torch involves understanding its components, selecting the right materials, and mastering various techniques. By implementing the strategies outlined in this article, you can enhance your welding skills and produce superior results. Remember, practice makes perfect, and continuous learning is key in the welding craft. Embrace the journey, and let your skills shine through your work!

TAG:

Related Posts

Unlocking the Potential of Your 250 Amp TIG Torch: Techniques to Try for Superior Welding Results