Essential Insights on TIG Torch Hose for Automotive Welding Applications

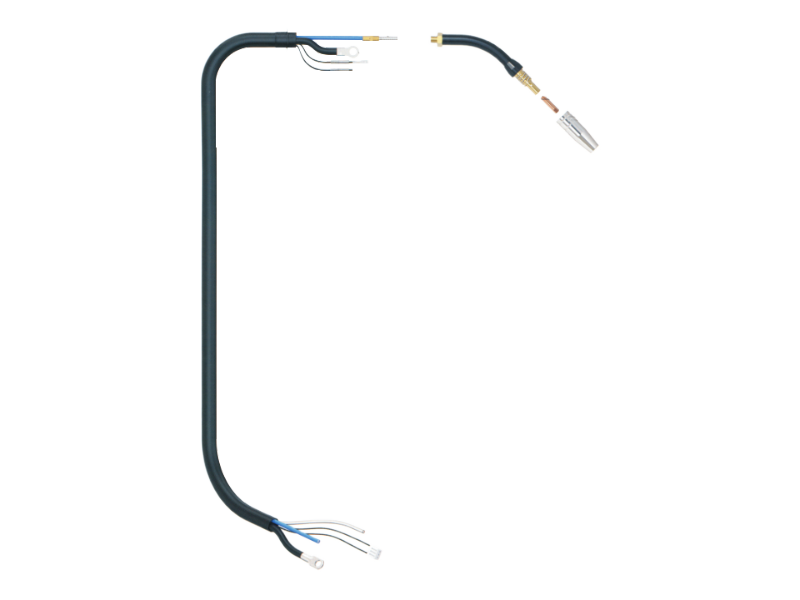

When it comes to TIG (Tungsten Inert Gas) welding, the quality of the equipment used can significantly impact the outcome of the weld. One of the critical components of the TIG welding setup is the TIG torch hose, which serves as the conduit for the shielding gas to flow to the torch. Understanding the intricacies of TIG torch hoses is essential for automotive professionals who demand efficiency a

When it comes to TIG (Tungsten Inert Gas) welding, the quality of the equipment used can significantly impact the outcome of the weld. One of the critical components of the TIG welding setup is the TIG torch hose, which serves as the conduit for the shielding gas to flow to the torch. Understanding the intricacies of TIG torch hoses is essential for automotive professionals who demand efficiency and reliability in their welding processes.

The TIG torch hose is typically made from high-quality materials that can withstand the pressures and temperatures associated with welding. Commonly, these hoses are constructed from rubber or thermoplastic elastomers, which offer flexibility and durability while resisting wear and tear. It is vital for professionals to choose a hose that meets the specific requirements of their welding applications, including checking for compatibility with the shielding gases being used, such as argon or helium.

Length and diameter are also key factors to consider when selecting a TIG torch hose. A longer hose may provide greater mobility but can lead to pressure drops, affecting the quality of the shielding gas flow. Conversely, a hose that is too short may restrict movement, causing strain on the equipment. Professionals should assess the workspace and choose a hose length that balances flexibility and functionality.

Another important aspect of the TIG torch hose is its connection to the torch and the gas supply. Proper fittings ensure a secure connection that prevents leaks, which can compromise the welding process. Regular inspection of the hose for signs of wear, such as cracks or abrasions, is essential for maintaining safety and efficiency. If any damage is detected, it is advisable to replace the hose immediately to avoid potential hazards during welding.

Moreover, maintaining the cleanliness of the TIG torch hose is crucial for optimal performance. Residue from welding materials can build up inside the hose, leading to blockages and reduced gas flow. Regular cleaning and proper storage when not in use can help prolong the life of the hose and ensure consistent performance.

In conclusion, the TIG torch hose is a vital component in the automotive welding process. By understanding its properties, selection criteria, and maintenance needs, professionals can enhance their welding capabilities and ensure high-quality results. Investing time in understanding this key element can lead to better performance and safety in welding applications.

The TIG torch hose is typically made from high-quality materials that can withstand the pressures and temperatures associated with welding. Commonly, these hoses are constructed from rubber or thermoplastic elastomers, which offer flexibility and durability while resisting wear and tear. It is vital for professionals to choose a hose that meets the specific requirements of their welding applications, including checking for compatibility with the shielding gases being used, such as argon or helium.

Length and diameter are also key factors to consider when selecting a TIG torch hose. A longer hose may provide greater mobility but can lead to pressure drops, affecting the quality of the shielding gas flow. Conversely, a hose that is too short may restrict movement, causing strain on the equipment. Professionals should assess the workspace and choose a hose length that balances flexibility and functionality.

Another important aspect of the TIG torch hose is its connection to the torch and the gas supply. Proper fittings ensure a secure connection that prevents leaks, which can compromise the welding process. Regular inspection of the hose for signs of wear, such as cracks or abrasions, is essential for maintaining safety and efficiency. If any damage is detected, it is advisable to replace the hose immediately to avoid potential hazards during welding.

Moreover, maintaining the cleanliness of the TIG torch hose is crucial for optimal performance. Residue from welding materials can build up inside the hose, leading to blockages and reduced gas flow. Regular cleaning and proper storage when not in use can help prolong the life of the hose and ensure consistent performance.

In conclusion, the TIG torch hose is a vital component in the automotive welding process. By understanding its properties, selection criteria, and maintenance needs, professionals can enhance their welding capabilities and ensure high-quality results. Investing time in understanding this key element can lead to better performance and safety in welding applications.

TAG:

Previous

Related Posts

Essential Insights on TIG Torch Hose for Automotive Welding Applications

When it comes to TIG (Tungsten Inert Gas) welding, the quality of the equipment used can significantly impact the outcome of the weld. One of the critical components of the TIG welding setup is the TIG torch hose, which serves as the conduit for the shielding gas to flow to the torch. Understanding the intricacies of TIG torch hoses is essential for automotive professionals who demand efficiency a