Cracking the Code: Common Questions About MIG Gun Parts

Getting to Know MIG Gun Parts

When it comes to MIG welding, the unsung heroes are undoubtedly the MIG gun parts. These components work tirelessly behind the scenes, ensuring smooth welding processes and high-quality results. But wait! You might be wondering, what are these parts exactly? Well, let's dive in!

What Exactly Are MIG Gun Parts?

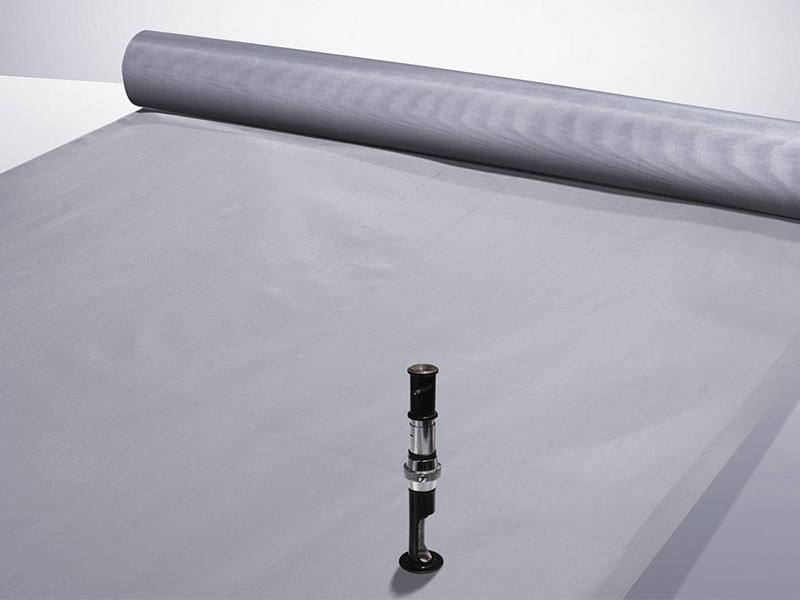

MIG gun parts refer to the various components that make up the MIG welding gun, an essential tool for any welder worth their salt. Think of it like the engine of a car; without the right parts, it just won't run smoothly. Key parts include the nozzle, contact tip, and liner, each playing a crucial role in delivering that perfect weld.

Common Questions About MIG Gun Parts

1. What's the deal with the contact tip?

Ah, the contact tip! It's like the cherry on top of your welding sundae. This little piece is where the welding wire enters the gun and gets electrified. The right contact tip size is essential for achieving the desired amperage and wire feed speed.

2. How often should I replace my MIG gun parts?

Well, that depends on how often you use your gun. If you're welding day in and day out, you might need to swap out those parts more frequently than a casual hobbyist. A good rule of thumb is to check them regularly and replace them at the first sign of wear.

3. Can I mix and match MIG gun parts?

In short, it's a risky business. While some parts may look similar, they often have specific designs and tolerances. Using the wrong parts can lead to poor performance or even damage your equipment. Stick with parts that are compatible with your MIG gun model.

Understanding the Parts: A Closer Look

Now, let's break it down a bit further. Here's a quick rundown of the primary MIG gun parts:

- Nozzle: The nozzle is the exit point for the shielding gas, protecting your weld from contamination.

- Contact Tip: As mentioned, this is where the magic happens. It's crucial for the wire feed.

- Liner: The liner guides the welding wire through the gun, ensuring a smooth feed.

- Trigger: The trigger controls the flow of gas and electric current, putting you in the driver's seat.

Troubleshooting Common Issues

Sometimes, things go awry in the world of MIG welding. Here are some common issues you might encounter with MIG gun parts:

1. Wire Feeding Problems: If your wire isn't feeding smoothly, it could be a clogged liner or a worn contact tip. Give it a good inspection!

2. Poor Weld Quality: If your welds are looking more like a spaghetti mess than a solid bead, check your nozzle and contact tip. They might need a swap.

3. Overheating: If your gun is heating up more than your favorite coffee, it's time to look at your duty cycle and ensure you're not pushing it too hard.

Final Thoughts

So, there you have it! A crash course on MIG gun parts and the common questions that arise. Remember, maintaining your equipment is half the battle in welding. Treat those MIG gun parts with care, and they'll serve you well for years to come. Happy welding!

TAG:

Previous

Previous:

Related Posts

Cracking the Code: Common Questions About MIG Gun Parts