Understanding Water-Cooled MIG Welding Machines: Benefits and Considerations

Water-cooled MIG welding machines are designed to provide superior cooling during the welding process, which is particularly beneficial for high-duty cycle applications. Unlike air-cooled machines, which rely on ambient air to dissipate heat, water-cooled systems utilize a water circulation mechanism. This allows for a more consistent and controlled cooling environment, which ultimately enhances t

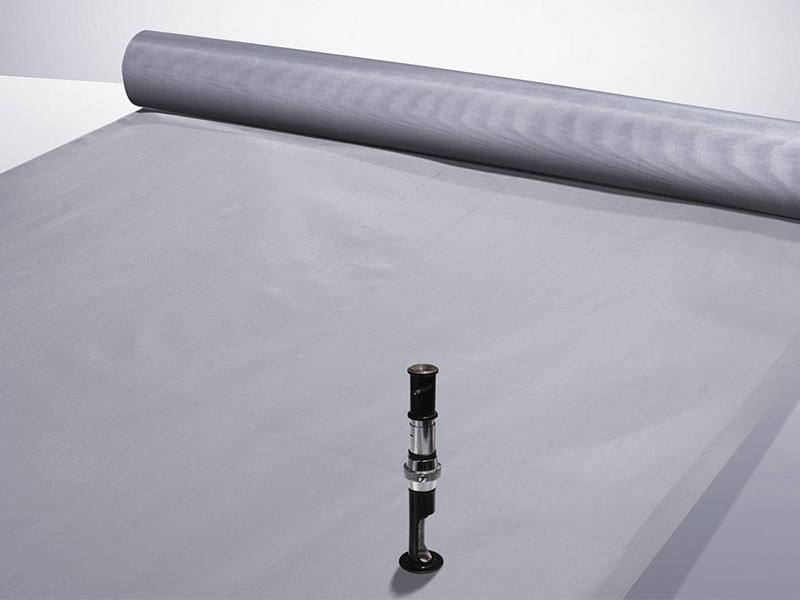

Water-cooled MIG welding machines are designed to provide superior cooling during the welding process, which is particularly beneficial for high-duty cycle applications. Unlike air-cooled machines, which rely on ambient air to dissipate heat, water-cooled systems utilize a water circulation mechanism. This allows for a more consistent and controlled cooling environment, which ultimately enhances the performance and longevity of the equipment.

One of the primary advantages of water-cooled MIG welding machines is their ability to handle higher weld currents without overheating. This is especially crucial when working on large projects or in industrial settings where continuous operation is required. The efficient cooling provided by water circulation means that welders can maintain higher productivity levels without the concern of equipment failure due to thermal stress.

Moreover, water-cooled systems tend to have a longer lifespan compared to their air-cooled counterparts. The reduced heat buildup results in less wear and tear on the machine components, which can lead to decreased maintenance costs over time. This durability is a significant consideration for professionals who depend on their equipment for regular use.

When selecting a water-cooled MIG welding machine, it’s important to consider the flow rate and temperature of the cooling water. An optimal flow rate ensures that the machine stays cool even during prolonged use, while the water temperature needs to be maintained within a suitable range to prevent other performance issues. Regular maintenance of the cooling system is also essential to ensure that it operates efficiently and effectively over time.

Additionally, water-cooled MIG welding machines are often more versatile than air-cooled models. They can accommodate a variety of welding processes and materials, making them suitable for different applications in the welding industry. This adaptability is advantageous for professionals who may be required to switch between tasks, as it minimizes the need for multiple machines.

In conclusion, water-cooled MIG welding machines offer significant benefits for industrial and high-demand applications due to their efficient cooling capabilities and durability. They are an excellent investment for professionals looking to maximize productivity and enhance the quality of their welding operations. When considering a water-cooled MIG welding machine, it’s essential to evaluate the specifications and maintenance requirements to ensure optimal performance in your specific welding environment.

One of the primary advantages of water-cooled MIG welding machines is their ability to handle higher weld currents without overheating. This is especially crucial when working on large projects or in industrial settings where continuous operation is required. The efficient cooling provided by water circulation means that welders can maintain higher productivity levels without the concern of equipment failure due to thermal stress.

Moreover, water-cooled systems tend to have a longer lifespan compared to their air-cooled counterparts. The reduced heat buildup results in less wear and tear on the machine components, which can lead to decreased maintenance costs over time. This durability is a significant consideration for professionals who depend on their equipment for regular use.

When selecting a water-cooled MIG welding machine, it’s important to consider the flow rate and temperature of the cooling water. An optimal flow rate ensures that the machine stays cool even during prolonged use, while the water temperature needs to be maintained within a suitable range to prevent other performance issues. Regular maintenance of the cooling system is also essential to ensure that it operates efficiently and effectively over time.

Additionally, water-cooled MIG welding machines are often more versatile than air-cooled models. They can accommodate a variety of welding processes and materials, making them suitable for different applications in the welding industry. This adaptability is advantageous for professionals who may be required to switch between tasks, as it minimizes the need for multiple machines.

In conclusion, water-cooled MIG welding machines offer significant benefits for industrial and high-demand applications due to their efficient cooling capabilities and durability. They are an excellent investment for professionals looking to maximize productivity and enhance the quality of their welding operations. When considering a water-cooled MIG welding machine, it’s essential to evaluate the specifications and maintenance requirements to ensure optimal performance in your specific welding environment.

TAG:

Related Posts

Cracking the Code: Common Questions About MIG Gun Parts

Explore the world of MIG gun parts with this engaging guide addressing common questions and insights.