Unlocking the Potential of MIG Gun Parts in Everyday Applications

The Unsung Heroes of Welding: MIG Gun Parts

Ever found yourself knee-deep in a welding project, only to realize that the MIG gun parts are the secret sauce behind your success? Well, you're not alone! Whether you're a seasoned pro or just dipping your toes into the molten metal world, understanding these components can elevate your welding game.

What Are MIG Gun Parts Anyway?

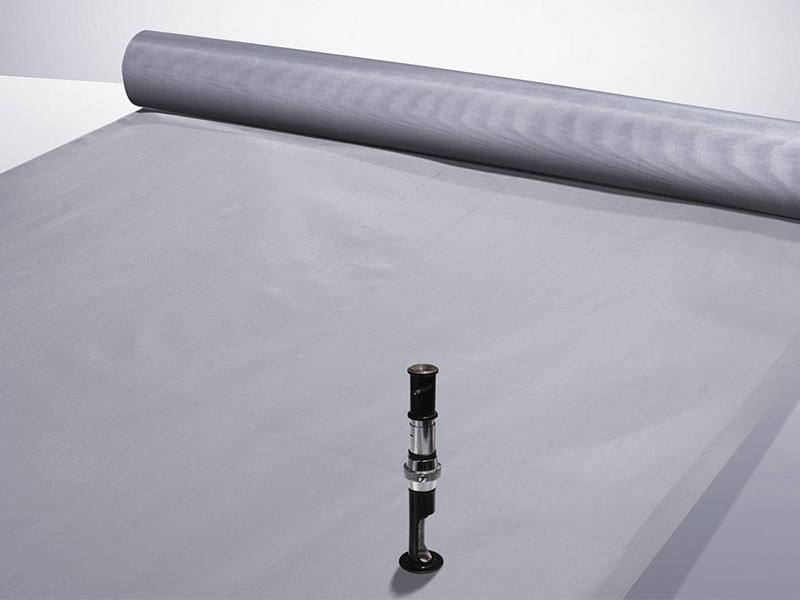

MIG, which stands for Metal Inert Gas, is a welding process that relies heavily on its gun parts. These include the contact tip, nozzle, liner, and trigger, each playing a pivotal role in delivering the perfect weld. Think of it like a well-oiled machine; if one part is off, the entire operation can go haywire!

Why Should You Care? The Applications Are Endless!

Here's the kicker: MIG gun parts are not just about functionality; they're about versatility! From automotive repairs to intricate artistic projects, these components can be found in a myriad of applications.

1. Automotive Repairs

Picture this: Your trusty old car is in dire need of some love. Using a MIG welder equipped with the right gun parts can make quick work of rusted panels or frame repairs. It's like giving your vehicle a second chance at life!

2. Home Improvement Projects

Whether it's crafting a custom fence or building a patio, MIG gun parts are your best buddies. They allow you to fuse metals seamlessly, making your DIY dreams a reality. Who knew welding could be so empowering?

3. Artistic Expressions

Artists are embracing the welding torch to create stunning sculptures and installations. The MIG gun parts enable them to manipulate metal with finesse, turning raw materials into breathtaking works of art. Talk about welding with a purpose!

Choosing the Right MIG Gun Parts

Alright, let's get down to brass tacks! Not all MIG gun parts are created equal. Depending on your application—be it thin sheet metal or heavy-duty steel—you'll need to select the right components. This is where doing your homework pays off.

Material Matters

Are you working with aluminum or stainless steel? Each material requires specific tips and nozzles. So, make sure you're not just grabbing whatever's available; that could lead to some serious headaches down the line!

Compatibility Is Key

If you're using a particular brand of welder, ensure that the MIG gun parts you choose are compatible. Otherwise, you might find yourself in a pickle—like trying to fit a square peg in a round hole!

Maintenance: Keep It Running Smoothly!

Now, let's not forget the importance of maintenance. Regularly inspecting and cleaning your MIG gun parts can prevent a mountain of trouble. After all, a stitch in time saves nine!

Cleaning Tips

Use a wire brush or a dedicated cleaning tool to remove any spatter or debris. A clean nozzle ensures a consistent gas flow, which is crucial for high-quality welds. So, get your hands dirty to keep things tidy!

Final Thoughts: The Art of Welding

In a nutshell, understanding MIG gun parts is essential for anyone looking to dive into the world of welding. They're not just components; they're the backbone of your welding adventures. So, whether you're patching up your car or crafting your next masterpiece, remember: those little parts pack a mighty punch!

TAG:

Previous:

Related Posts

Unlocking the Potential of MIG Gun Parts in Everyday Applications