CO2 Welding Torch Material: A Comprehensive Guide to Enhance Your Welding Skills

Are you interested in expanding your knowledge about CO2 welding torch material? In the electrical and electronics industry, welding and cutting materials play a vital role in achieving the desired results. This comprehensive guide will provide you with valuable insights into the materials used in CO2 welding torches, enabling you to enhance your welding skills and achieve superior results.

1. Understanding CO2 Welding Torch Material:

CO2 welding torches are widely used in the electrical and electronics industry for their efficiency and versatility. The materials used in these torches significantly impact the welding process and the quality of the weld. Let's explore the essential materials that make up CO2 welding torches.

2. Torch Body:

The torch body is usually made of high-quality heat-resistant materials such as brass, aluminum, or stainless steel. These materials ensure the durability and long lifespan of the torch, even in high-temperature welding environments. Additionally, they provide excellent conductivity to facilitate efficient welding operations.

3. Handle and Insulation:

CO2 welding torches feature ergonomic handles designed to provide a comfortable grip and reduce operator fatigue during extended welding sessions. The handles are typically insulated with materials like rubber or heat-resistant plastics to protect the operator from electrical shocks and excessive heat.

4. Electrode Holder:

The electrode holder, also known as the contact tip holder, is an integral part of the CO2 welding torch. It holds the electrode securely and ensures proper electrical contact. Copper and copper alloys are commonly used materials for electrode holders due to their excellent conductivity and resistance to heat.

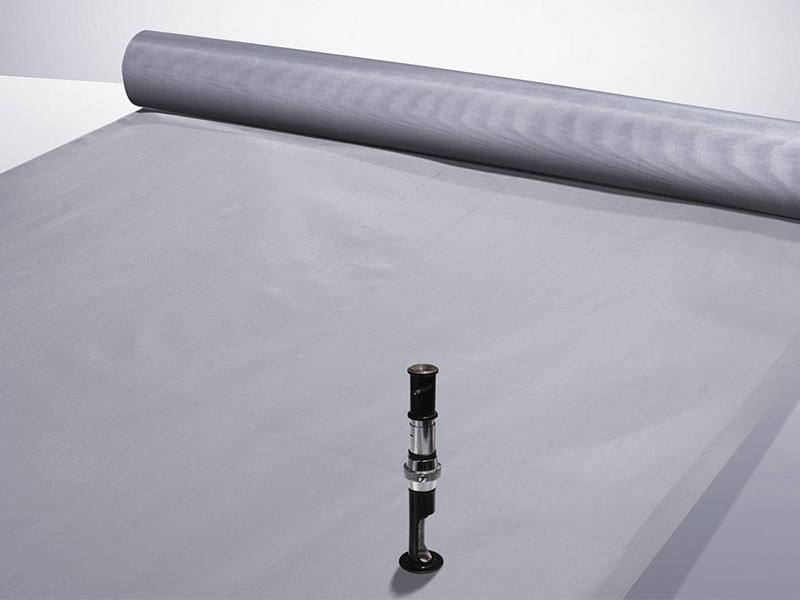

5. Nozzle and Diffuser:

The nozzle and diffuser assembly in a CO2 welding torch helps regulate gas flow, shielding the weld pool and preventing oxidation. These components are typically made of copper alloys, which provide good thermal conductivity and resist the corrosive effects of welding gases.

6. Contact Tip:

Contact tips are responsible for transferring the welding current to the electrode wire. They are usually made of copper or copper alloys to ensure optimal electrical conductivity and resistance to heat. The contact tip size and shape can vary based on the specific welding application.

7. Benefits of Different Materials:

Using the right materials in CO2 welding torches offers several benefits. For example, brass torch bodies provide excellent durability and heat resistance, while aluminum torch bodies offer lightweight and corrosion resistance. Copper electrode holders ensure efficient current transfer, and copper alloy nozzles and diffusers resist corrosion. Understanding these benefits helps optimize welding processes.

Conclusion:

Mastering CO2 welding requires a good understanding of the materials utilized in the welding torch. By familiarizing yourself with the materials mentioned above, you'll be better equipped to choose the right CO2 welding torch for your electrical and electronics welding needs. Remember, selecting the appropriate materials enhances both the efficiency and quality of your welding projects, leading to outstanding results.

TAG:

Related Posts

Unlocking the Magic of MIG Gun Parts: A Comprehensive Guide